Reactive Alumina

to achieve superior physical properties with ultra fine particles

ALPHA company offers a wide range of reactive alumina used in the refractory industry. Reactive alumina is a subcategory of calcined alumina which is fully ground down so a significant part of the particles has reached the size of the constituent crystal size. Reactive aluminas are specially designed for the production of high-performance refractories where defined particle packing, rheology and consistent placement characteristics are as important as the superior physical properties of the final product. Porosity in agglomerates helps water absorption and limits crystal growth during sintering. Reactive alumina is used in the castable matrix, providing lower water demand and regulating rheology by controlling particle size distribution. Otherwise, high mixing water may be required and the product may suffer from inadequate physical properties or water and aggregate separation after casting.

Advantages:

- Enabling full flexibility in design of refractory matrix

- High technical flow control

- Providing high packing density

- Adjust rheological properties of castables

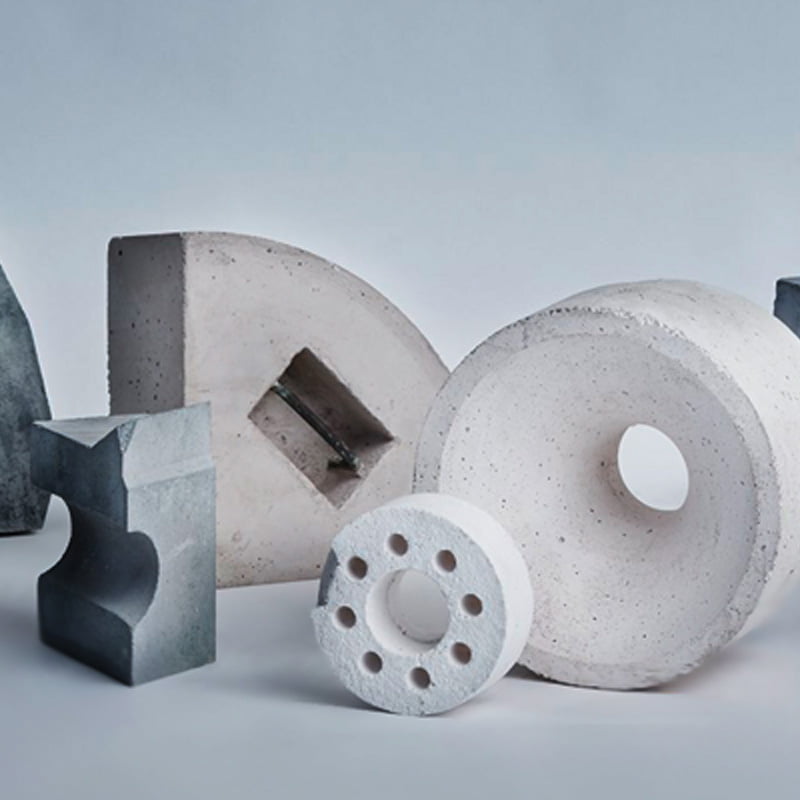

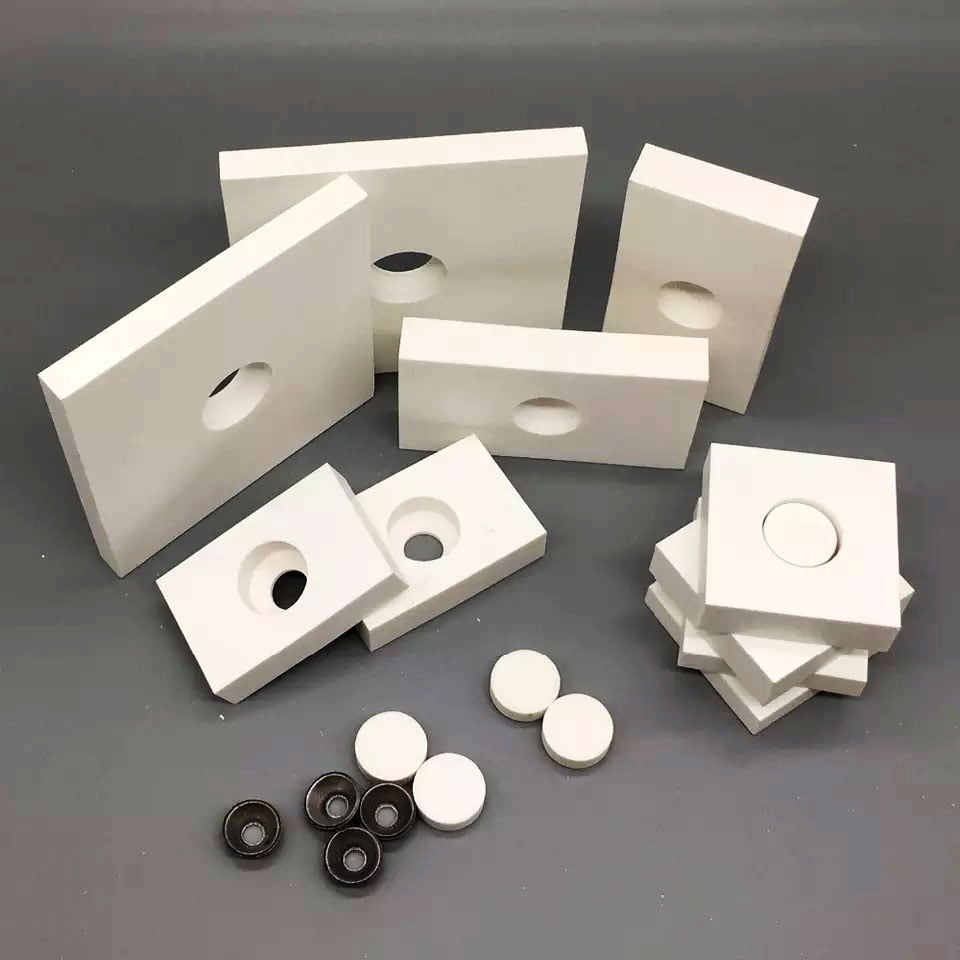

Applications:

- Low, ultra-low and No cement castables

- Gunning and shotcrete mixes

- Nozzles, lances, purging sets, sleeves

- High-performance bricks and sliding gate plates