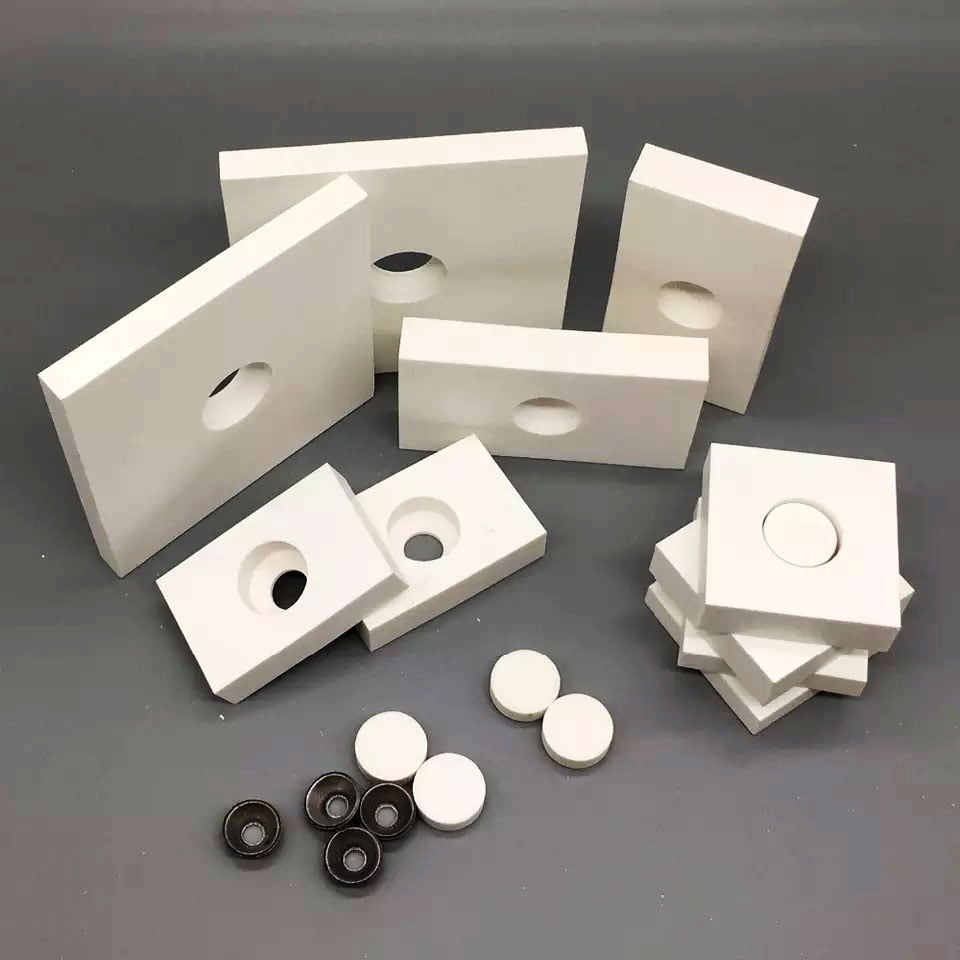

Grinding Media Lining Wear Parts

One of the special applications of wear-resistant ceramic is grinding media and surface coatings for ball mills. Ball mills are currently considered an essential component in the process of preparing materials in various industries such as tile and ceramic, porcelain and glaze, paint and cement, and powder making, but in all industrial ball mills, corrosion And the wear of the ball and the body of the mill is a big problem, and if the grinding materials are sensitive to metal contamination, this problem becomes more apparent, for this reason, in the ceramic, tile, porcelain and sanitary porcelain industries, ball mills The material of the balls and the body (liner) is ceramic so that the least contamination enters the raw materials. The main ceramic material used for these applications is alumina.

ALPHA offers different grades of calcined alumina with various particle size distributions, soda content and specific surface area suitable for use as grinding media, linings and wear parts.

The meticulous manufacturing process leads to complete control of products' properties and a suitable product for every technical ceramic.

ALPHA