Honeycomb Ceramics

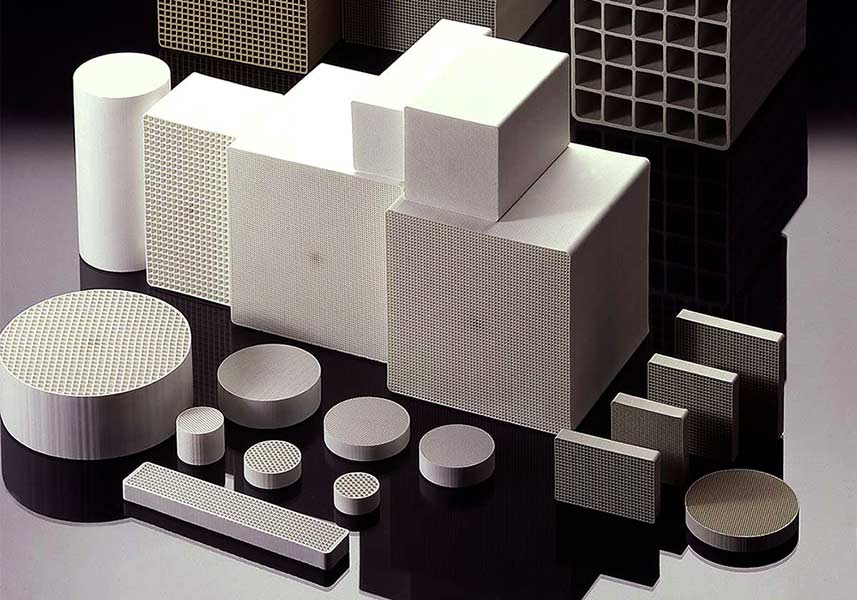

Honeycomb ceramics are one of the advanced aspects of the ceramic industry. The cellular structure of these ceramics, as it appears in the name, was inspired by the nature. The advances in manufacturing methods in the ceramic industry in recent decades have allowed us to produce honeycomb structures in an integrated and uniform manner. This structure creates unique properties for the product, which makes it possible to use it in many different applications.

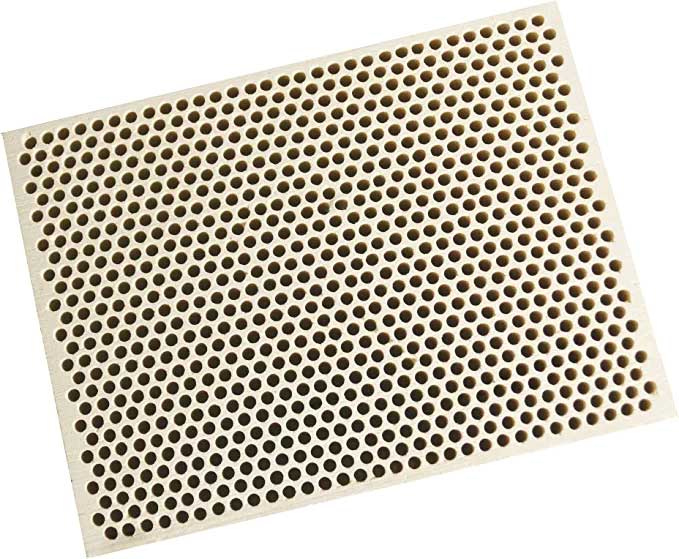

Honeycomb ceramics can have up to 40 holes per square centimeter in their structure. One of the distinctive features of honeycomb ceramics is the more surface that they can create in equal volumes compared to other structures. Despite the porosity in these ceramics, the structure of its walls is such that the overall strength of the product is very good and it is fully capable of enduring harsh working conditions. In these ceramics, the thickness of the walls is very low, which creates two features that are very important in flow-related applications: First, the low thickness of the walls creates a wide inlet space and reduces the back pressure of the gas, and as a result of this thickness, the pressure loss along the channels will be reasonable.

structure and the resulting properties of these ceramics make them very ideal for many different applications. Honeycomb ceramic can be used in various filtration processes. One of the first and primary uses of honeycomb structures is emission filtration in the automotive industry and generally any other stationary emission devices. These ceramics also are a very good choice for catalyst application. They can be used as catalyst support and the different active component will be loaded on them. Also, it is possible to produce a honeycomb structure from active material. One of the main applications of honeycomb ceramics is as heat storage media in different systems, especially regenerative burners and they can also be used in heat exchangers.

Honeycomb ceramics can be produced from different raw materials and the properties of the final product can vary depending on the choice of raw material. Aluminum oxide powder is one of the important materials which is used for manufacturing these ceramics and it can create unique properties for them. ALPHA offers different grades of calcined alumina with various particle size distribution, soda content and specific surface area.

The meticulous manufacturing process leads to complete control of products' properties and a suitable product for every technical ceramic.

ALPHA