Calcined Alumina (α-Alumina)

to achieve remarkable versatility and functionality

ALPHA offers calcined alumina (α-Alumina) products suitable for a wide range of applications. Calcined alumina is a type of aluminum oxide that has been heated to over 1200°C to remove almost all of the chemically incorporated water and transform to the alpha phase. These products are classified according to their calcination degree, soda content and grinding mechanism. Considering calcination degree, they are classified as Hard Calcined and Medium Calcined. Higher calcination degrees of alumina leads to more crystal growth and higher alpha phase content. The soda content of calcined alumina is precisely controlled in order to achieve higher refractoriness and improved high-temperature mechanical properties. The soda content is classified as Normal Soda, Medium Soda, Low Soda and Ultra Low Soda. Depending on final usage, calcined alumina is used unground or ground. Grinding may be done in batch milling process or continuous milling processes including ball milling and jet milling. In a batch mill, milling is continued until the complete disintegration of particles into their constituent crystals, leaving no residual agglomerates. In continuous milling, more amounts of agglomerates are left behind. The water absorption of alumina is defined by the amount of residual agglomerates.

Advantages:

- High density

- High refractoriness

- Hardness and high resistance to wear and crushing

- High chemical stability

- High heat capacity

- High melting point (more than 2050 degrees Celsius)

- Dielectric properties

- Insulation of electricity

Applications:

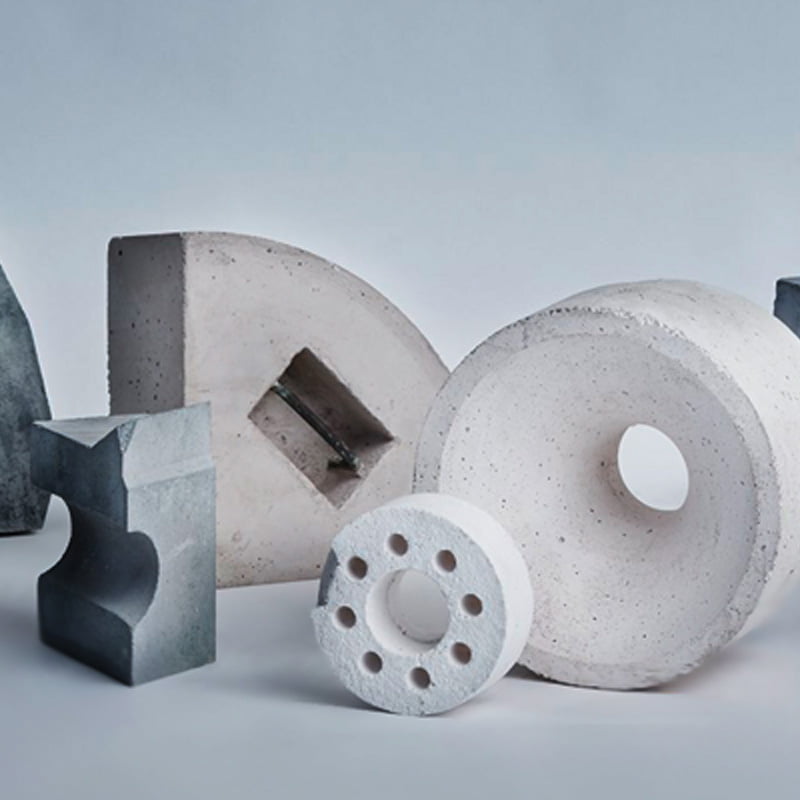

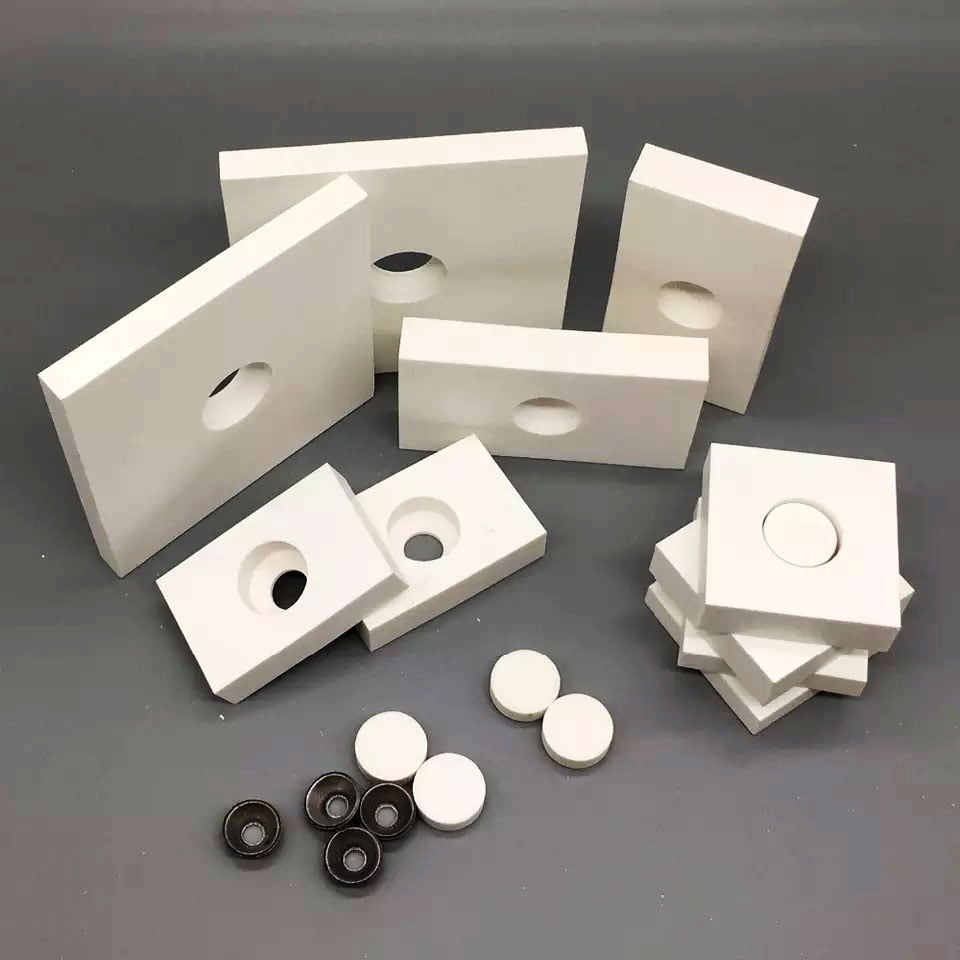

- Shaped refractories like bricks, tubes, tiles, etc.

- Unshaped refractories like gunning mixes, castables, ramming mixes, etc.

- Catalysts

- Grinding media, lining and wear parts

- Honeycomb ceramics

- Glazes and engobes

- Sanityware & tableware

- And many other applications