Flame Retardant

Starting and sustaining a fire requires the presence of combustible material, heat and sufficient oxygen. Flame retardant is an additive that is mixed with combustible materials such as polymers, and by disrupting the performance of the three mentioned factors or disrupting the chemical reaction, it prevents the occurrence of fire or its spread or reduces the speed of its spread. In some cases, the retardant is applied as a coating on the surface. Another very important task of the flame retardant is to reduce heat and smoke production.

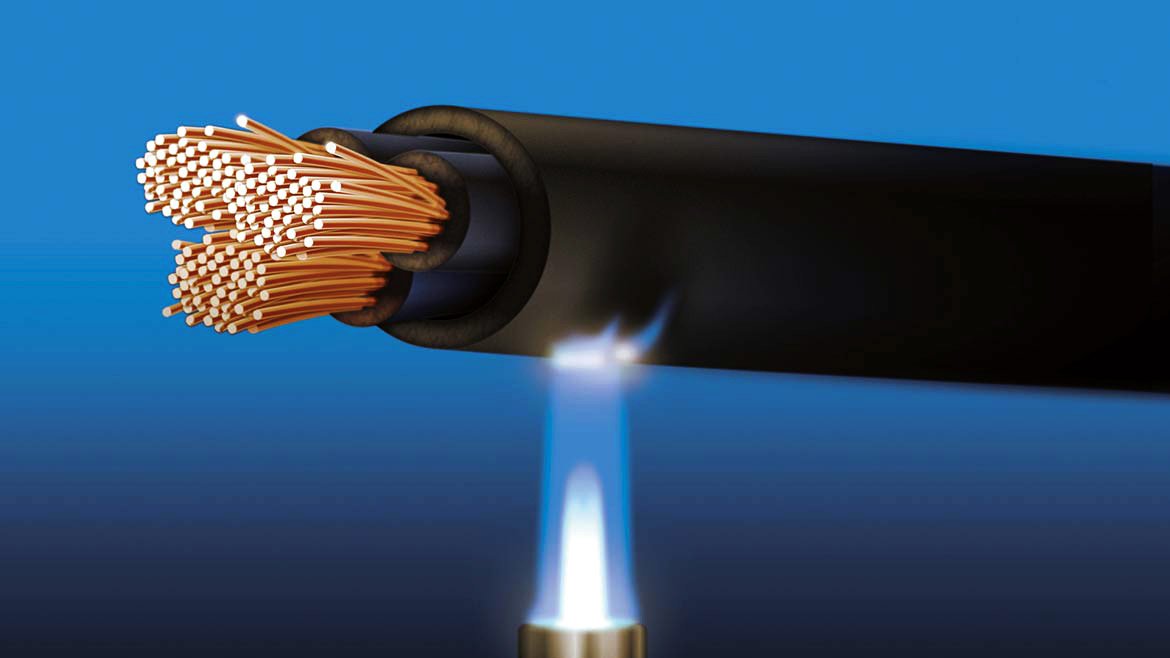

In many cases, fire happens imperceptibly. For example, one of the most common causes of fires in houses and other places is the short circuit of electrical devices. Therefore, preventing the occurrence of fire, extinguishing it in the early stages or slowing down its progress can reduce much damage and the importance of flame retardants is clear.

The first generation of flame retardants was made of halogen compounds but pollution caused by the production of these flame retardants, smoke toxicity caused by their burning, and pollution caused by plastic waste made them obsolete. Nowadays the largest share in the market of flame retardants is held by mineral flame retardants. These materials have been used in various domestic and industrial applications. Mineral flame retardants are generally composed of hydrated metals. They are halogen-free and can be reprocessed. They are free from environmental pollution and have a little destructive effect on the equipment. They also play a role in reducing smoke and dripping.

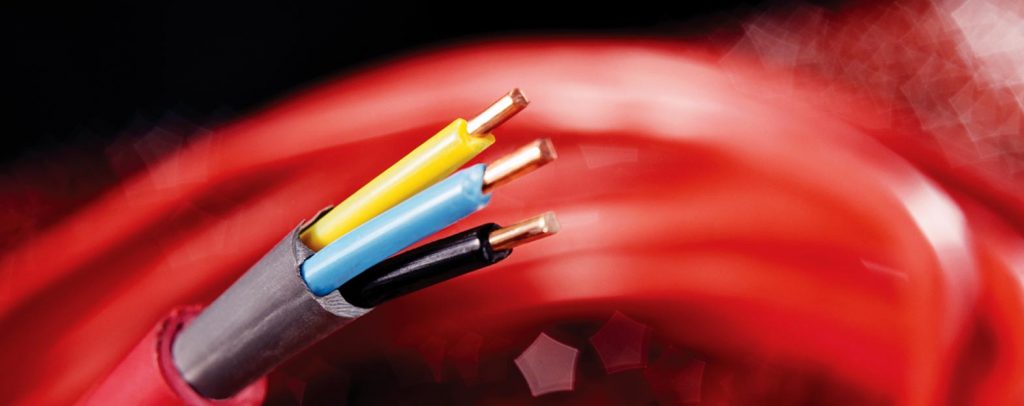

Aluminum trihydoxide (ATH) is one of the most widely used mineral flame retardants. These particles are decomposed in an endothermic way and produce water. As a result, the polymer is cooled and the ignition is delayed. The release of water has the role of diluting the gas phase, it acts as a protective gas layer on the solid phase; It reduces the percentage of oxygen and also reduces the concentration of oxidizing substances. Also, the use of mineral particles reduces the amount of polymer in the final product, which is another reason for reducing fire. ATH is white and produced in different particle sizes. The choice of particle size is made according to the type of application and expected thermal and mechanical properties. However, in terms of retardant performance, the smaller the particles, the better. In addition to the particle size, the uniform distribution of the ATH strongly affects their efficiency. Aluminum hydroxide is used in a wide range of equipment. It is used in wire and cable coating, pipe, flooring, ceiling, injection parts and films.

ALPHA offers ATH with good purity and in many different particle size distributions ideal to use as a flame retardant material.

By implementing high-efficiency technologies we are the producer of effective flame retardants additives for different parts.

ALPHA